The selection of resilient floor and wall panel systems within the United Kingdom’s dynamic architectural and construction sectors necessitates a rigorous, data-driven approach. Beyond aesthetic and cost considerations, material specification must demonstrably conform to the stringent performance criteria articulated in UK Building Regulations and harmonized European Norms (EN).

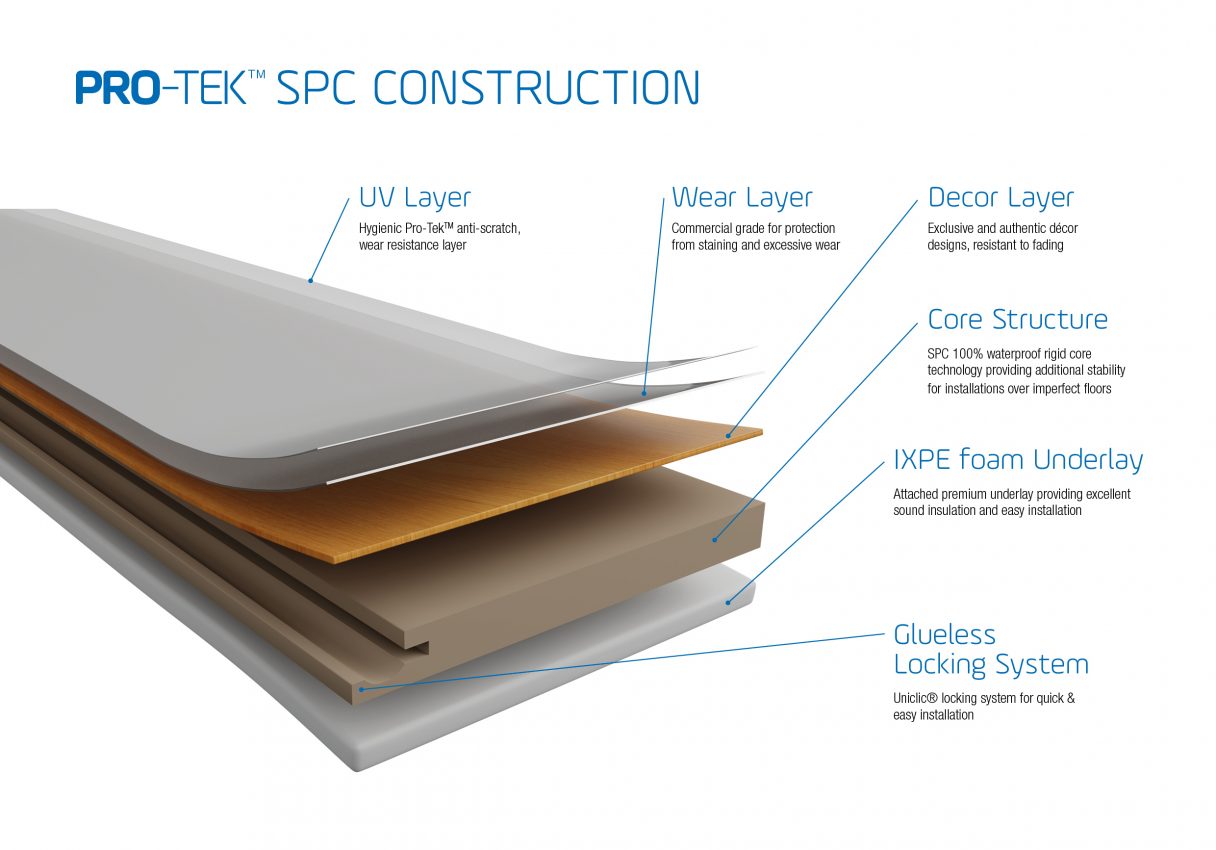

Pro-Tek™ flooring (comprising both Stone Plastic Composite—SPC—and Wood Plastic Composite—WPC—variants) and Pro-Tek™ SPC Wall Panels represent a modern class of high-performance vinyl-based surfaces. This guide details the third-party verification against critical metrics, ensuring consistent quality and full regulatory adherence.

Jump to Section:

- Critical Safety: Fire Ratings (EN 13501-1)

- Slip Resistance Analysis (HSE Guidelines)

- Indoor Air Quality & VOCs

- Mechanical Durability (Indentation, Wear & Impact)

- Independent Verification (IFL)

- Technical FAQ (Full List)

Critical Safety: Fire Ratings (EN 13501-1)

The Reaction to Fire performance is arguably the most critical safety parameter for interior surface materials, forming the basis of Part B (Fire Safety) of the UK Building Regulations.

Pro-Tek™ SPC and WPC flooring systems consistently achieve a Bfl-s1 rating.

This classification is the highest practical class for any combustible flooring product and denotes two critical attributes:

- Bfl (Minimal Contribution to Fire Spread): Proven by a high critical radiant flux (CRF) of ≥8.0 kW/m² (EN ISO 9239-1). This ensures the flooring does not significantly contribute to flame propagation, vital for safe egress in hospitals and high-rise blocks.

- s1 (Very Limited Smoke Generation): The ‘s1’ designation is the best classification available for smoke density. It indicates minimal total smoke production, dramatically improving visibility during evacuation.

Compliance Check: High-Occupancy Corridors

- Application: Escape routes in Schools, Hospitals, or Offices.

- Requirement: Must meet high fire safety standards for egress.

- Pro-Tek™ Result: Bfl-s1. Meets or exceeds the default requirement for most public building escape routes (which often only require Cfl-s1).

Slip Resistance Analysis (HSE Guidelines)

Slip resistance is a fundamental requirement for risk mitigation under the Health and Safety Executive (HSE) guidelines in the UK.

1. Wet Slip Resistance – Pendulum Test (BS 7976)

The Pendulum Test is the HSE’s preferred method for measuring Dynamic Coefficient of Friction (DCOF).

- Pro-Tek™ Result: PTV >36 (Low Slip Risk).

- Application: Commercial washrooms, utility rooms, and retail entrance lobbies susceptible to moisture.

2. Dry Slip Resistance – Dynamic Friction (EN 13893)

- Pro-Tek™ Result: DS Classification. Confirms a secure walking surface under normal, dry operating conditions.

Compliance Check: Risk Management

- Standard: BS 7976 (Pendulum Test)

- Requirement: Legally defensible evidence of due diligence for preventing slips.

- Pro-Tek™ Result: Low Slip Risk (36+). Appropriate for public-facing areas.

Indoor Air Quality & VOCs

Material specification places increasing emphasis on Indoor Air Quality (IAQ), driven by health and wellness standards (ISO 16000).

- A+ VOC Rating: Pro-Tek™ surfaces have attained the highest possible A+ rating under French regulations (using ISO 16000 methodology), signifying minimal emission concentrations.

- Formaldehyde-Free: Testing under standard GB 18580 confirms emissions are well below detection limits.

- Phthalate-Free: Independent analysis confirms a 100% Phthalate-Free composition, ensuring a non-toxic polymer structure suitable for healthcare and schools.

Mechanical Durability (Indentation, Wear & Impact)

Commercial flooring must resist static and dynamic loads over an extended service life.

A. Residual Indentation (EN ISO 24343-1)

Measures recovery after a static load (e.g., hospital beds, cabinets) is applied.

- Pro-Tek™ Result: ≤0.10 mm.

- Significance: Meets the stringent requirement for Commercial Class 34/43, ensuring the SPC core remains structurally sound under pressure.

B. Dimensional Stability (EN ISO 23999)

Assesses warping under thermal stress (e.g., direct sunlight or Underfloor Heating).

- Pro-Tek™ Result: ≤0.05% change.

- Significance: Far superior to the permitted 0.25%, making it uniquely suited for conservatories and UFH systems.

C. Castor Chair Resistance (EN 425)

Simulates the abrasive movement of office chairs.

- Pro-Tek™ Result: Pass (No visible damage after >25,000 cycles).

D. Wear Layer & Abrasion (EN 660-2)

- Abrasion Group: Group T (Highest classification for flexible floor coverings).

- Wear Layer: Commercial grade (0.55mm – 0.70mm).

E. Adhesion and Impact Resistance

- Peel Resistance (EN ISO 24345): Testing confirms strong mechanical adhesion between the polymeric wear layer and the rigid SPC core. High peel resistance is critical for preventing delamination, especially in perimeter zones or areas subject to cleaning with hot water or steam.

- Impact Resistance (EN ISO 6603): This verifies the floor’s ability to absorb and withstand sudden, sharp dynamic forces (e.g., dropped tools or commercial goods) without chipping, cracking, or catastrophic failure.

Independent Verification (IFL)

In the age of digital specification, architects require impartial data. Pro-Tek™ partners with the Independent Flooring Laboratory (IFL)—an ISO-accredited third-party organization.We commit to batch-specific verification across 20+ key performance indicators. This removes the risk of manufacturing variance and provides a verifiable Chain of Custody for performance data, a key requirement for UK procurement standards.

Technical FAQ

Fire Safety & Compliance

- Q1: What is the Bfl-s1 fire rating for Pro-Tek™ flooring?

- A: The Bfl-s1 rating under EN 13501-1 ensures minimal contribution to fire spread (Bfl) and very low smoke emission (s1). This rating is critical for escape routes, commercial corridors, and high-occupancy areas, fully meeting UK Building Regulations Part B.

- Q2: Are Pro-Tek™ SPC Wall Panels fire-rated?

- A: Yes. Pro-Tek™ panels achieve a B-s1,d0 rating, meaning limited fire spread, minimal smoke, and no flaming droplets, making them suitable for both residential and commercial interiors.

- Q3: Can Pro-Tek™ panels and flooring be used in escape routes?

- A: Absolutely. Both are fire-rated for safe use in corridors, stairwells, and emergency exits, meeting the strictest UK standards.

- Q4: How do Pro-Tek™ panels compare with traditional tiles for fire performance?

- A: Unlike ceramic tiles, which can crack under heat, Pro-Tek™ panels maintain fire resistance while offering impact resilience. They combine safety and durability in high-traffic areas.

Slip Resistance & Safety

- Q5: How does Pro-Tek™ SPC flooring achieve a low-slip risk rating?

A: Pro-Tek™ flooring passes the Pendulum Test (BS 7976) with a Pendulum Test Value (PTV) ≥36, the HSE’s threshold for low slip risk. This makes it suitable for wet commercial areas like kitchens, washrooms, and entrances. - Q6: Are wall panels slip-resistant?

A: Panels are not tested for slip as they are vertical surfaces, but they feature smooth, safe edges to reduce the risk of impact-related injuries. - Q7: Is Pro-Tek™ suitable for commercial wet areas?

A: Yes. Flooring is low-slip rated, and wall panels are non-porous and moisture-resistant, ideal for showers, kitchens, and high-humidity zones.

Durability & Dimensional Stability

- Q8: Can Pro-Tek™ flooring be used with underfloor heating (UFH)?

- A: Yes. SPC cores demonstrate minimal thermal expansion (≤0.05% under EN ISO 23999 at 80°C), preventing warping, gapping, or curling under UFH systems or intense sunlight.

- Q9: How resistant are Pro-Tek™ wall panels to impact?

- A: Panels meet EN 438-2:2005 standards, showing excellent resistance to scratches, dents, and knocks, suitable for busy kitchens and commercial areas.

- Q10: Are Pro-Tek™ products UV-resistant?

- A: Yes. Both panels and flooring maintain colour stability under sunlight, tested under EN ISO 105-B02 standards.

- Q11: Can flooring handle heavy commercial traffic?

- A: Yes. Abrasion testing (EN 660-2) confirms exceptional wear resistance, making it ideal for offices, retail, hospitality, and healthcare facilities.

- Q12: How do wall panels resist moisture?

- A: Panels are 100% waterproof, showing no swelling, delamination, or warping even in high-humidity or water-exposed areas.

Chemical & Environmental Safety

- Q13: Are Pro-Tek™ products low-VOC?

- A: Yes. They achieve an A+ rating (ISO 16000 series), ensuring excellent indoor air quality for schools, healthcare, and residential settings.

- Q14: Are they formaldehyde and phthalate-free?

- A: Yes. Independent chemical testing confirms they are free from phthalates and have formaldehyde levels far below regulatory limits.

- Q15: Can Pro-Tek™ panels resist common household chemicals?

- A: Yes. Panels pass EN 438-2:2005 chemical resistance tests, protecting surfaces from detergents, mild acids, and cleaning agents.

- Q16: Are Pro-Tek™ products recyclable?

- A: Yes. Both flooring and wall panels are fully recyclable, supporting sustainable building practices.

Testing & Verification

- Q17: Why is Independent Flooring Laboratory (IFL) verification important?

- A: IFL provides impartial, batch-specific testing, verifying fire, slip, and chemical performance. This is essential for public sector and large commercial projects where compliance and risk mitigation are critical.

- Q18: Are all Pro-Tek™ batches independently tested?

- A: Yes. Every shipment undergoes verified testing for fire, slip resistance, and chemical safety.

- Q19: Can I request certificates of compliance for my project?

- A: Absolutely. Pro-Tek™ provides batch-specific test certificates and documentation on request.

- Q20: What international standards do Pro-Tek™ products meet?

- A: Flooring: EN 13501-1 (fire), EN 660-2 (abrasion), BS 7976 (slip). Wall panels: EN 438-2:2005 (durability, moisture, chemical), ISO 16000 (VOC emissions).

- Q21: How often are products retested?

- A: Annual internal audits plus batch-specific independent verification ensure consistent compliance and quality.

Installation & Maintenance

- Q22: Can wall panels be installed over existing tiles?

- A: Yes, provided the surface is flat and clean. Approved adhesives or mechanical fixings ensure a durable installation.

- Q23: Do SPC floors require adhesive?

- A: Most use a click-lock system, reducing or eliminating adhesive use, making installation quicker and easier.

- Q24: Is cutting Pro-Tek™ products safe on-site?

- A: Yes. Standard woodworking tools can be used safely. Dust masks are recommended in enclosed areas.

- Q25: How should Pro-Tek™ products be cleaned?

- A: Flooring: damp mop with mild detergent. Wall panels: wipe with a soft cloth or sponge and non-abrasive cleaner.

- Q26: Do panels require sealing after installation?

- A: No. Pro-Tek™ panels have dual-layer protective coatings on both décor and grout lines, eliminating the need for additional sealing.

Commercial & Residential Applications

- Q27: Are Pro-Tek™ products suitable for commercial kitchens?

- A: Yes. Flooring is slip-resistant and panels are moisture- and grease-resistant, perfect for high-traffic kitchens.

- Q28: Can panels be used as splashbacks?

- A: Yes. Their non-porous, stain-resistant surfaces make them ideal for kitchens, bathrooms, and wet areas.

- Q29: What thicknesses are available?

- A: Panels: 8–10mm. Flooring: 4–8mm, depending on collection and intended application.

- Q30: How do Pro-Tek™ products compare with traditional tiles regarding testing?

- A: Pro-Tek™ undergoes more frequent, rigorous third-party batch testing, verifying fire, slip, chemical, and dimensional performance, ensuring superior compliance and reliability in UK projects.